Grit SS - Fully Integrated Gravel

$11,845.00 AUD - $14,923.00 AUD

The Grit SS is our innovative gravel frameset that sets new standards in its class. Leveraging advanced manufacturing processes, including die-cast headtubes, 3D-printed yokes, 3D-printed dropouts, and hydroformed tube profiles, the Grit SS achieves a perfect balance of enhanced aerodynamics, reduced weight, and unwavering strength. Inspired by the design principles of our flagship Strada SS road model, the Grit SS emerges as a faster and more focused counterpart to our adventure-oriented Grit SX. With a lighter, more aerodynamic frameset and tighter geometry, the Grit SS elevates its performance both on the road and off. The Grit SS is packed with Utility so you're not compromising performance for practicality. Clearance for 700x50c tyres, mounting points in all the right places, fully integrated for the cleanest aesthetics, all backed by our 50 year warranty - it doesn't get better than this.

BUILD KITS

Rival AXS XPLR E1

Bossi Grit SS frameset

SRAM Rival AXS E1 XPLR groupset

Bossi Nomad carbon wheelset

Bossi integrated carbon gravel cockpit

Prologo Nago saddle

Pirelli Cinturato M Gravel 45c tyres

Bossi black bartape

Tubeless

FORCE AXS XPLR E1

Bossi Grit SS frameset

SRAM Force AXS E1 XPLR groupset

Bossi Nomad carbon wheelset

Bossi integrated carbon gravel cockpit

Selle Repente Artax carbon saddle

Pirelli Cinturato M Gravel 45c tyres

Bossi black bartape

Tubeless

Force AXS XO E1

Bossi Grit SS frameset

SRAM Force AXS E1 groupset

XO Transmission rear derailleur

Bossi Nomad carbon wheelset

Bossi integrated carbon gravel cockpit

Selle Repente Artax carbon saddle

Pirelli Cinturato M Gravel 45c tyres

Bossi black bartape

Tubeless

RED AXS XPLR E1

Bossi Grit SS frameset

SRAM RED AXS E1 XPLR groupset

Bossi Nomad carbon wheelset

Bossi integrated carbon gravel cockpit

Selle Repente Artax carbon saddle

Pirelli Cinturato M Gravel 45c tyres

Bossi black bartape

Tubeless

BOSSI BIKE BUILDER

Your Bossi journey starts here. The frameset is your canvas, choose every component in our Bike Builder and submit your design. We hand-build to order in-house. No presets, no compromises, a bike that delivers the fit, feel, and performance no off-the-shelf build can match.

Book Your Free Consultation

The build options outlined above serve to provide estimated costs only. We have access to a diverse selection of groupset and components. If you don't find the exact build you're looking for, feel free to reach out, and we'll be happy to provide a tailored quote. Whether you're seeking guidance on your custom build or have questions about our designs, use the link below to schedule a consultation. We're here to address all your inquiries.

Frame features

- Aero die-cast 6AL/4V head tube

- Hydroformed 3AL/2.5V aero down tube

- Hydroformed 3AL/2.5V top tube with bag mounts

- Ovalised and tapered 3AL/2.5V chainstays

- Tapered 3AL/2.5V seatstays with rack mounts

- 3D Printed 6AL/4V size specific dropouts

- 3D printed 6AL/4V chain stay yoke

- CNC 6AL/4V 86mm T47 bottom bracket

- Fully integrated cable routing

- 3x bidon mounts

- Triple fork rack mounts

- 12mm thru axle (12x100mm front, 12x142mm rear)

- Flat mount disc brake

- SRAM UDH (supplied with direct mount hanger option)

- 27.2mm seat post

- Seatstay bridge

- Chainstay bridge

- Full fender mounts

- Chain holder on seatstay

- CNC headtube logo

- Laser engraved downtube logos

- Brush finish

- 700x50c tyre clearance, 27.5” x 2.2”

- Electronic groupsets only

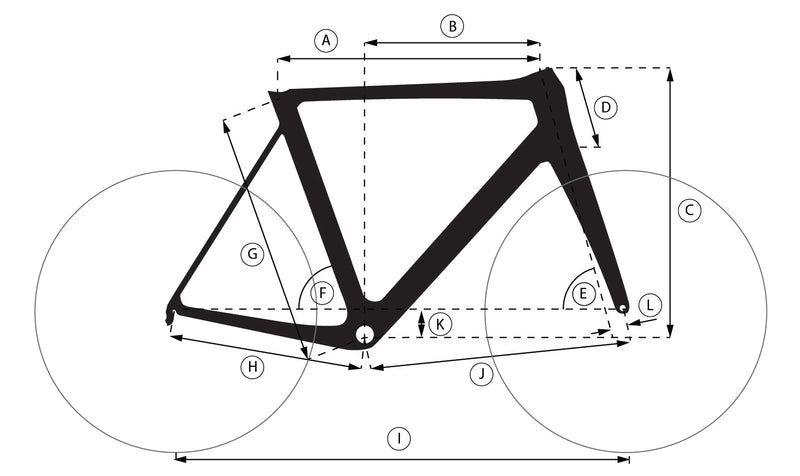

Geometry

Promo: Free EKAR GROUPSET

Campagnolo’s Ekar groupset doesn’t get the recognition it deserves. light, reliable, and designed for adventure. We’ve had two kits sitting on the shelf for too long, and we’d rather see them out on the road than gathering dust.

So here’s the offer: order a complete custom Bossi build and we’ll include your Ekar groupset, free of charge.

Specs:

Crankset = 170mmx44T

Cassette = 9-42T

Rotors = 160/160

Only one left! First come firt serve!

PROJECT: DREAM BIKE

Your dream bike project starts here. A Bossi frameset is your blank canvas—build something extraordinary.

PRODUCTION STATS

35 Hours

Total time to produce a single frame. Every Grit SS frame is meticulously crafted. Hours spent on cutting, mitring, CNC machining, tube preparation, welding, polishing, laser engraving, frame prep and QC. Precision, passion, and craftsmanship in every detail.

6 hours

Time it takes to weld a single frame. Double-passed welding : the first ensures deep penetration and fusion, while the second refines the weld, enhancing strength, durability, and aesthetics while reducing defects and contamination.

8 hours

Time it takes to polish a Grit SS. Linishing every weld and brushing the surface to perfection. This labor-intensive process ensures a flawless finish, highlighting the craftsmanship behind every frame.

2 hours

Post fabrication frame preparation. Every Bossi frame is faced, reamed, and tapped after welding ensuring that all contact points are perfect and ready for assembly. An extra step in QC rarely matched by other brands.

4210 + 15%

Tested to exceed ISO 4210 standards by 15%. Both in terms of load and number of cylces. Ensuring superior durability, and reliability beyond industry requirements. We test to failure in every production run to maintain our strict standards.

THIRTEEN

Number of QC inspections our frames go through before being approved. From individual parts to full frame. Every detail is inspected and confirmed.

ONE HUNDRED

Percantage of frames that undergoe QC by Bossi staff, ensuring flawless craftsmanship, precision, and quality before it reaches the rider.

NINETY

Percentage of processes involved in crafting a Bossi frame that are done by hand. including cutting, mitring, welding, polishing, alignment checks, and final finishing. Made by artisans, with love.

five

Our frames are handmade, and while minor imperfections can occasionally occur, we reject and recycle around 5% of frames that don’t meet our stringent quality control standards. This selection process is costly but ensures only the best frames reach our customers. This level of transparency and commitment to quality is rare in the industry.

order process

General: Please provide preferred groupset specification, bar and stem sizing, and component colours in checkout notes. We will get in touch to discuss the finer details.

Custom Builds: Looking for something a little different? Get in touch with our team to discuss quotation for a custom build. We're more than happy to help you flesh out your dream machine.

Lead time: General lead times are 4-8 weeks before dispatch. This is subject to component availability and may vary.

Shipping

We offer free domestic and international shipping on orders over $200. Please visit the shipping page below for more information.

ShippingContact form

Contact Us Today!

If you have questions about any of our products or would like to schedule a consultation to plan a custom buld, feel free to get in touch.